Nissan Frontier EV Conversion: Turning a Gas Truck into an Island-Ready Electric

Introduction

What happens when you take a beloved Nissan Frontier pickup—solid, capable, but thirsty on gas—and give it a modern electric heart?

You get the best of both worlds: a quiet, torquey daily driver that's still at home on dirt roads and beach access trails, but without the fuel bills or emissions.

This is the story of one of our signature builds at ReRides EV: a 2000 Nissan Frontier 4x4 converted to electric using proven Nissan Leaf components, custom fabrication, and a lot of problem-solving tailored to Hawaiʻi's unique driving conditions.

If you've ever wondered whether your truck could make a good EV candidate, this build shows what's possible—and what it takes.

Why Convert a Nissan Frontier?

The Frontier is a popular choice for island life: compact enough for town, tough enough for adventure, and simple enough to work on. But like most early-2000s trucks, it wasn't exactly fuel-efficient.

For this project, our goals were clear:

Daily island driving: Commutes, errands, and regular trips around Oʻahu.

Occasional off-road use: Surf parking and light trail driving.

Lower running costs: Hawaiʻi gas prices make electric power especially attractive.

Keep the 4x4 capability: No compromises on ground clearance or drivetrain layout.

The Frontier's body-on-frame construction, spacious engine bay, and straightforward drivetrain made it a strong candidate for conversion. The challenge? Packaging batteries without losing bed space or ride height, and integrating an electric motor that could handle both highway cruising and low-speed torque.

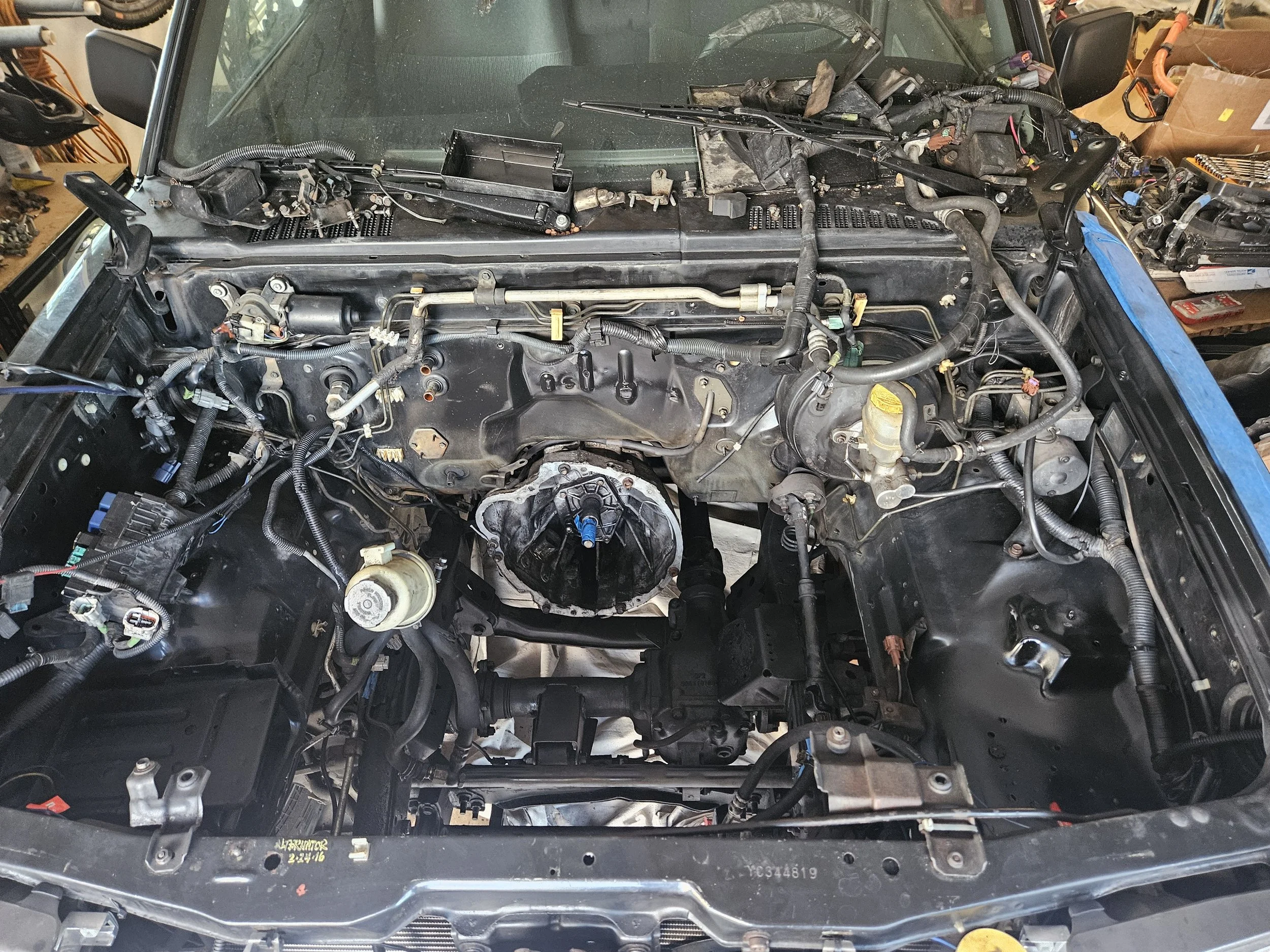

The Starting Point: A Truck That Needed a Second Life

Every conversion starts with a donor vehicle. In this case, the Frontier arrived on a tow truck—mechanically sound but no longer running. That's actually ideal: we could focus the budget on the electric conversion rather than fixing an aging combustion engine.

The first step? Strip out everything related to the old internal combustion engine.

Out came:

The internal combustion engine (ICE).

The fuel tank, exhaust system, and emissions equipment.

Coolant lines, fuel lines, and other ICE-specific plumbing.

A/C compressor and power steering pump

What stayed? The frame, suspension, steering, brakes, 4x4 transfer case, and even the transmission —everything that makes a Frontier a Frontier.

The Electric Drivetrain: Proven Nissan Leaf Components

Rather than reinventing the wheel, we built this conversion around Nissan Leaf donor parts—a proven, reliable, and widely available platform.

What we reused from the Leaf:

Electric motor: Compact, efficient, and plenty of torque for a truck this size.

Inverter: Converts DC battery power to AC for the motor.

Battery modules: Lithium-ion cells sized to provide practical range for island driving.

High-voltage contactors and wiring: Safety-critical components that control power flow.

Onboard Charger and DC/DC Converter: Charger and converter are already correctly sized for the other HV components

Using Leaf parts keeps costs reasonable, reduces waste (we're reusing components from salvage vehicles), and leverages a well-documented system that's been proven in hundreds of thousands of cars.

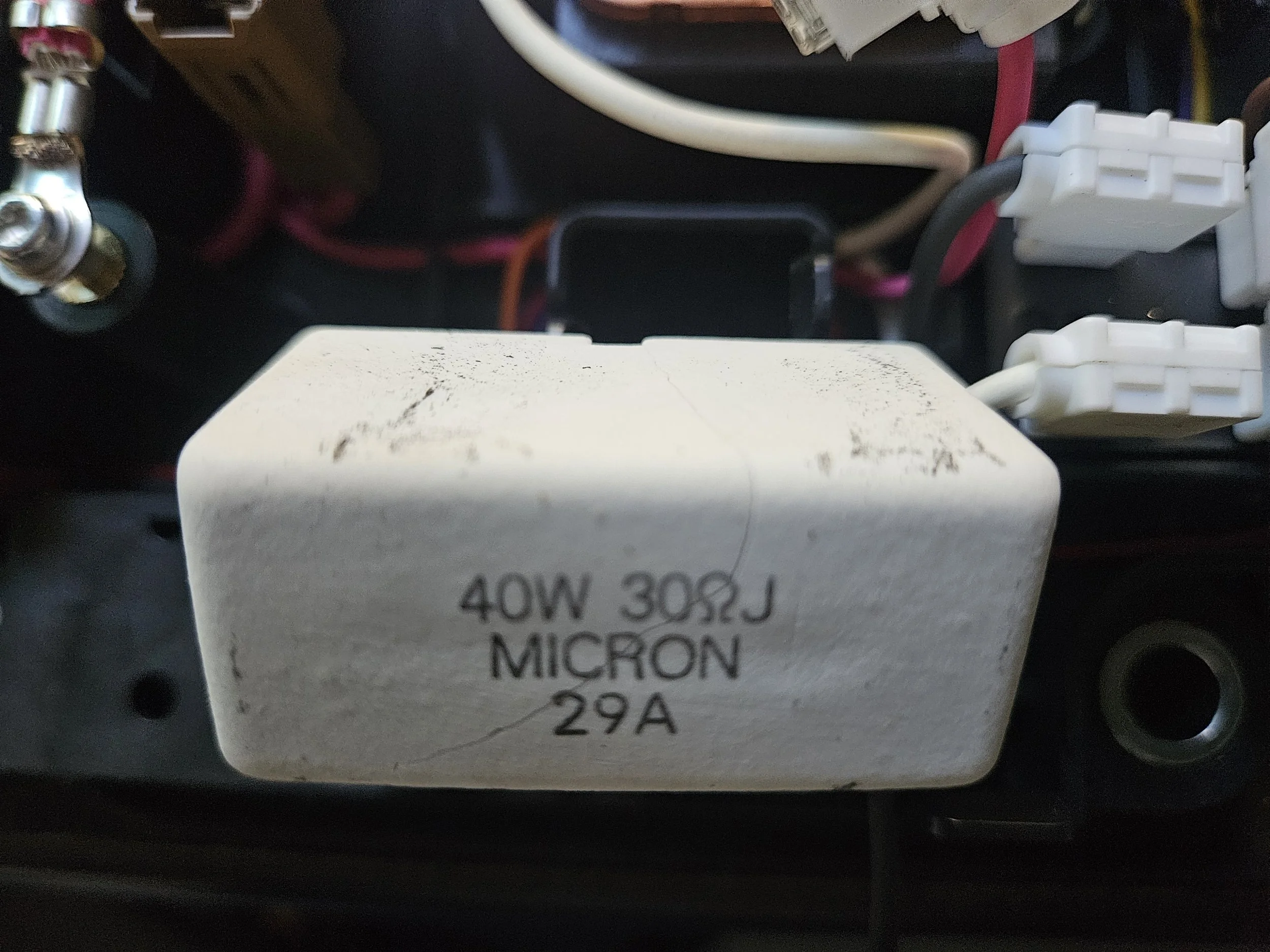

But reused parts aren't plug-and-play. Every component gets inspected, tested, and refurbished as needed.

For example, we discovered a failed precharge resistor in the contactor assembly—a small but critical part that safely charges the system before the main contactors close. We replaced it before installation, avoiding a potential failure down the road.

Custom Fabrication: Making It Fit

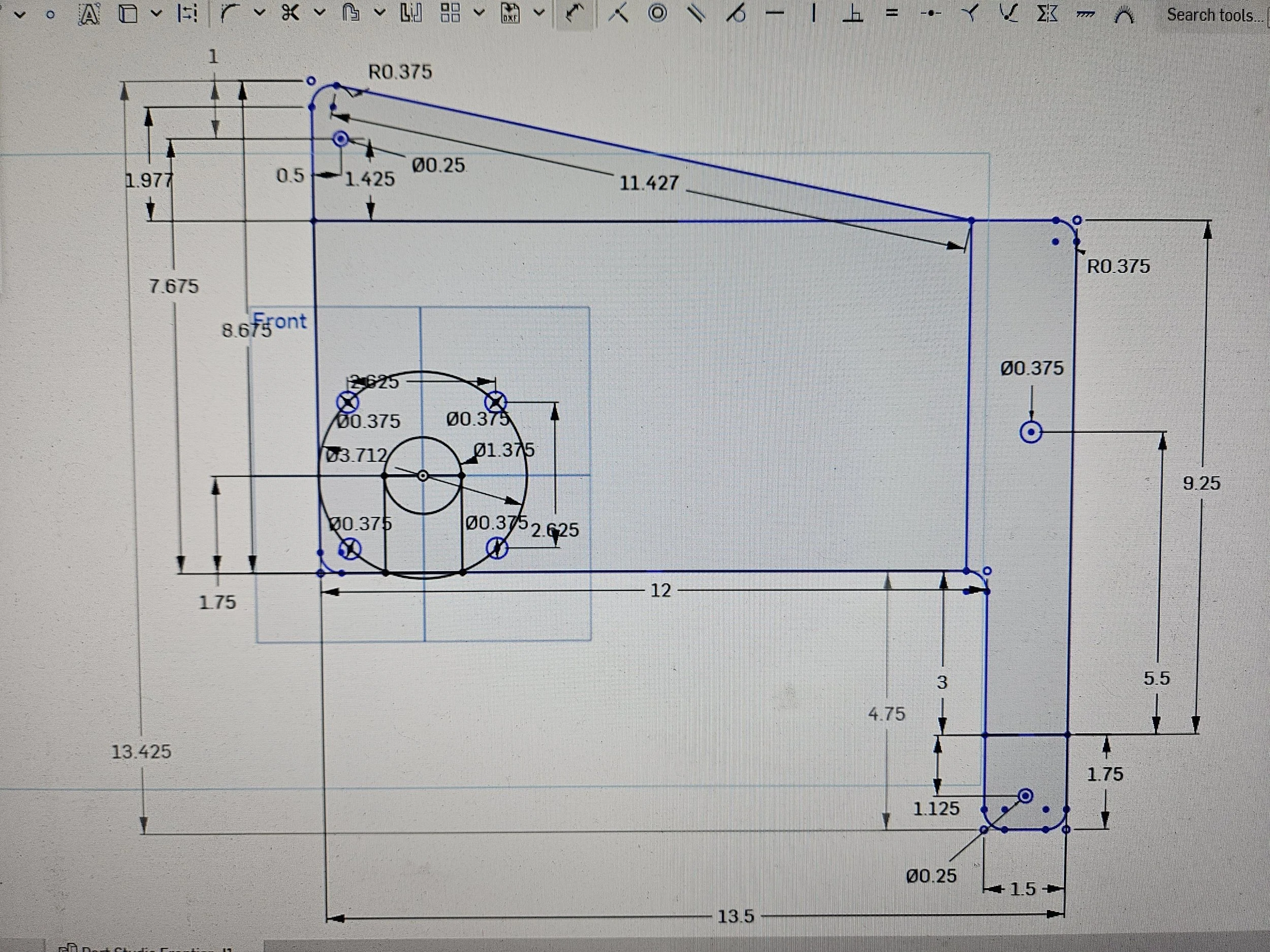

Off-the-shelf EV conversion kits don't exist for the Frontier, so we designed and fabricated custom components to mate the Leaf motor to the truck's drivetrain and mount accessories.

Key custom parts:

Motor mount: Single pieces cut, drilled, and bent from CAD file.

Motor coupler: Connects the motor shaft to the transmission input shaft.

Motor adapter plates: Bolts the Leaf motor to the Frontier's transmission bellhousing.

CAD engineering: Precise measuring, integration of manufacturer’s dimensions, with single-piece fabrication and corrosion protection

We also designed a custom battery pack layout to fit under the truck without compromising ground clearance or bed space. The pack is securely mounted to the frame and protected from road debris and water.

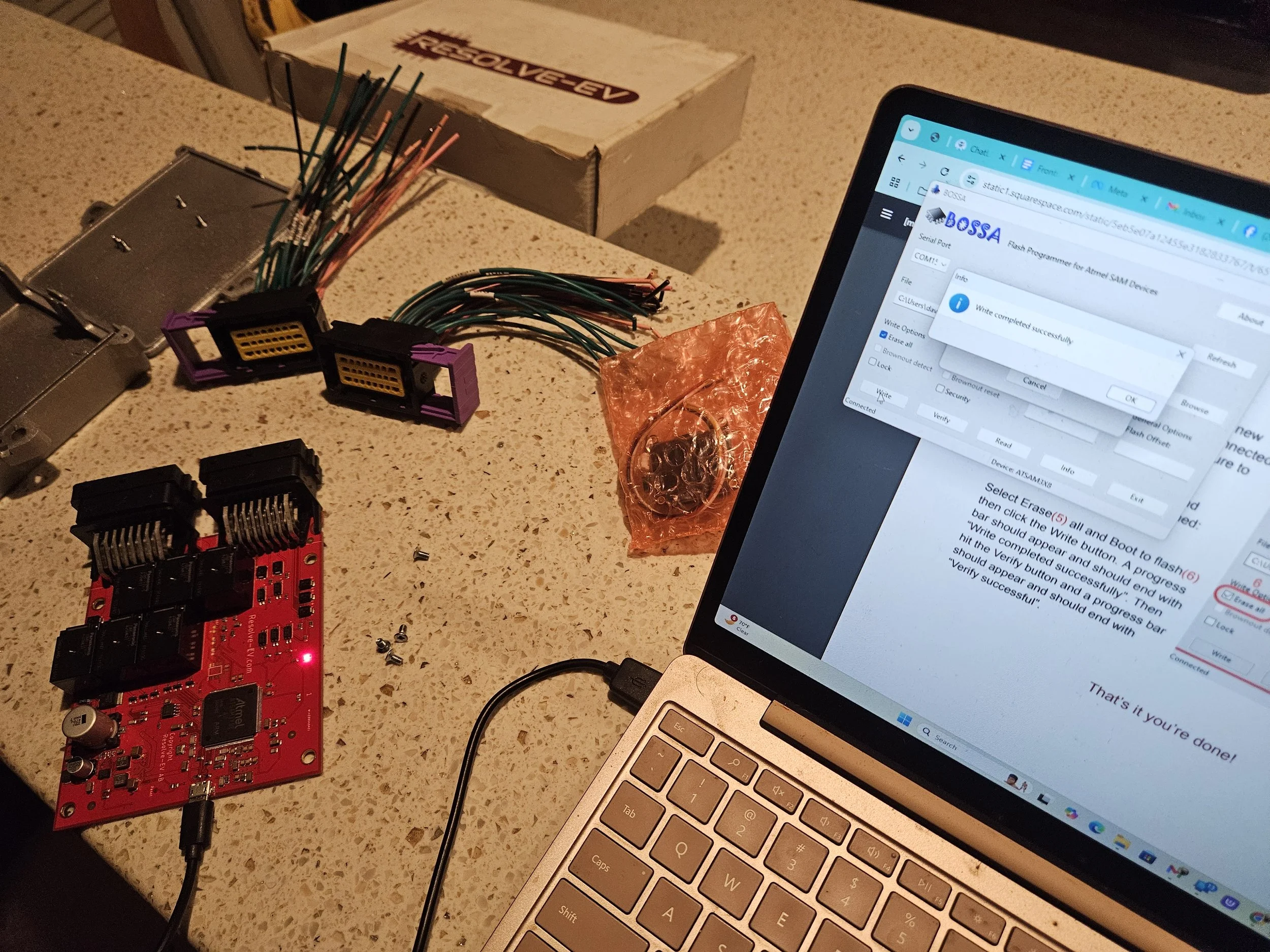

Modern Control Systems

To manage the motor, battery, and vehicle integration, we used a combination of:

Reused Leaf inverter and control boards for known compatibility.

Commercial EV controller hardware for minimal configuration.

Custom instrumentation controls to integrate with the Frontier's original dash, ignition, and safety systems.

The result? The truck starts with the original key, shifts into drive with a simple selector, and behaves like a modern EV—just in a familiar Frontier body.

The Finished Result: A Quiet, Capable Island Truck

After several weeks of design, fabrication, and testing, the Frontier was ready for the road.

What we delivered:

Enough range for daily island driving: Sized for typical Oʻahu trips without needing a massive (expensive) battery pack.

Instant torque: Electric motors deliver full torque from zero RPM, making the truck feel surprisingly quick off the line.

Quiet, smooth operation: No engine noise, no vibration, no exhaust smell.

Lower running costs: Charging at home is cheaper than filling up at Hawaiʻi gas prices.

4x4 capability intact: The transfer case and drivetrain layout were preserved, so the truck is still capable off the pavement.

What We Learned: Why Pickups Make Great EV Candidates

The Frontier project reinforced a few key lessons:

Pickups have space: Engine bays and frames offer room for motors and batteries without major compromises.

Practical use cases fit EV range well: Most island driving is short trips, which is ideal for electric.

Reusing proven components works: Leaf parts are reliable, affordable, and well-suited to truck conversions.

Custom fabrication is key: Every vehicle is different, and thoughtful design makes the difference between a "project car" and a daily driver.

If you have a mid-size pickup you love but don't love the gas bills, an EV conversion might be a great fit.

Thinking About Converting Your Truck?

Every build is custom, and pricing depends on your vehicle, range goals, and performance priorities. Many full conversions for pickups like this Frontier land somewhere in the $20,000–$40,000 range, depending on battery size and complexity.

Want to explore what's possible for your truck?

Get a Conversion Consultation →

We'll walk through your vehicle, how you drive, and what a conversion could look like for you.